Once leader material reaches a certain thickness, knots become an imperfect means of connecting hooks, swivels and lures, and creating loops for attaching snaps. From about 80-pound-test and up (be it monofilament or fluorocarbon leader line), knots don’t easily cinch tight, grow awkwardly large, and might unravel. Crimps, on the other, offer a solid and streamlined grip.

As with knots, crimps represent a critical connection between you and fish, and so they must be created using the proper crimp sleeves, tools and techniques. To learn more about this, we talked with Capt. Shawn Rotello, owner and operator of Night Runner sportfishing charters in Kona, Hawaii. Rotello targets blue marlin, yellowfin tuna and wahoo, as well as ulua (giant trevally) in the lee of the Big Island. Here are his tips for creating good crimps using a hand crimper.

Pick the Best Sleeve Size

First, make sure the crimp sleeve is properly sized to the line, says Rotello. “If the sleeve is too small, the line won’t fit inside; if it’s too large, the sleeve might not crimp tight enough to keep the line from slipping,” he explains. Hi-Seas makes it easy by labeling the packaging for the crimp sleeves to fit specific pound-test ratings. You can also match the diameter of the sleeve to the diameter of the leader. Each should be labeled on the packaging for the sleeves and leader material.

Aluminum Versus Copper Sleeves

Crimp sleeves for monofilament and fluorocarbon come in two styles: oval aluminum and double-barrel copper. Anglers debate on which is best, but Rotello offers this advice: “I tend to use the double-barrel copper sleeves for leaders of 130-pound-test and less, because they seem a tad more gentle on the lighter line.” For 150-pound-test and up, the skipper uses aluminum sleeves. For thicker leaders, the sleeves are correspondingly larger, and the lighter aluminum material keeps the weight down for better lure and live-bait action.

The Sleeve Length

Crimping sleeves come in two sizes: short and long. Short sleeves are a better choice for lighter leaders and/or line-shy fish. The long sleeves are better for heavier leaders and situations in which the crimp will not be visible, such as inside the skirt of a trolling lure or within a rigged bait.

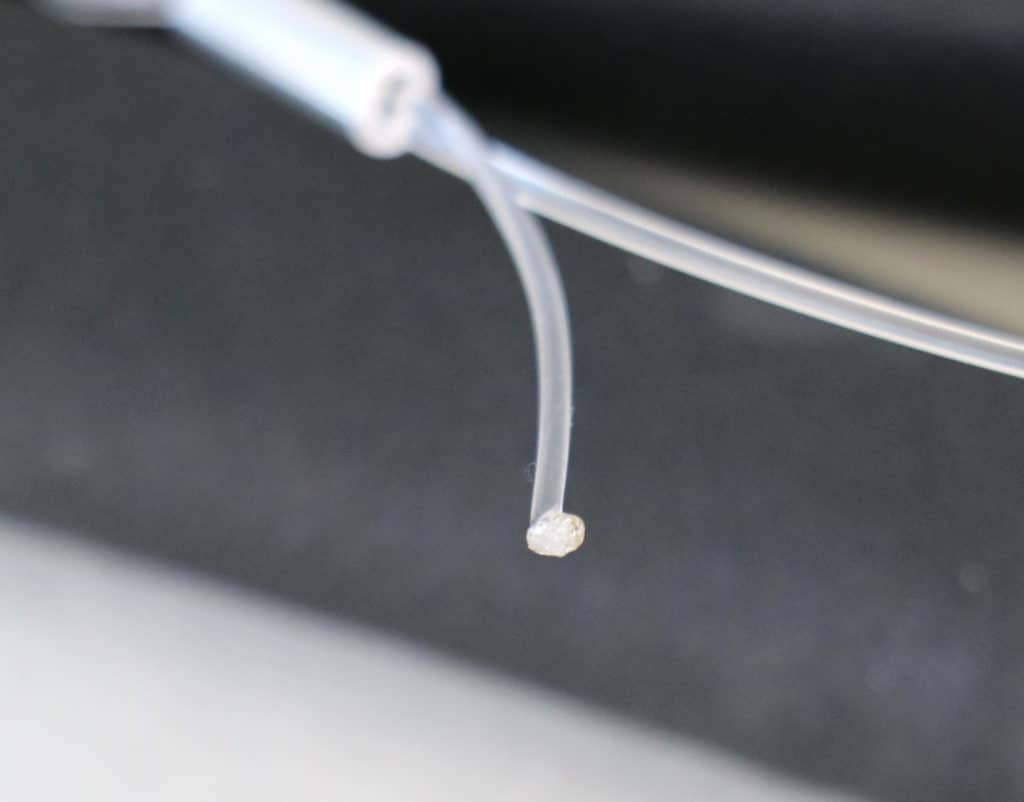

Melt the Tag End

Rotello recommends this step before actually crimping: After you’ve threaded the leader through one end of the sleeve and back through the other end of the sleeve, pull out about 3 or 4 inches of the tag line. “Use a lighter to melt the tip of the tag line,” he says. “This creates a blob of material on the end of the tag line that helps prevent it from pulling out of the crimp.” Once it is cool, pull the end of the tag flush with the end of the crimp.”

Don’t Kink the Loop

This tip applies to loops crimped without thimbles or other chafe protection. As you are tightening the loop, avoid making it too small. It should be just large enough to prevent the loop from kinking.

Match Diameters

The jaws of a crimping tool such as the Hi-Seas Deluxe mini hand crimper have multiple indentations known as dies. This allows for crimping different sizes of sleeves. Match the size range stamped next to the die to the inside diameter (ID) of the sleeve. For copper sleeves, use the ID of one of the barrels. For oval aluminum sleeves, use the shortest inside dimension.

One or Two Crimps

With a long sleeve, crimp it at least twice, once each about 2 to 4 millimeters from the ends of the sleeve. With a short sleeve and a thick-jawed crimper, there is usually not enough room for two crimps, so just crimp once in the center. “It is important not to crimp too close to the end of the sleeve, as this may damage or nick the leader line,” Rotello says. “Leave enough room so that the end of the sleeve flares a bit.”

Perfect Pressure

If you don’t crimp a sleeve with enough pressure, the line can slip out. Too much pressure can damage the leader line and cause it to break. A quality crimping tool such as the Hi-Seas Deluxe mini hand crimper comes calibrated for applying just the right amount of pressure to create secure crimps that do not damage the line.

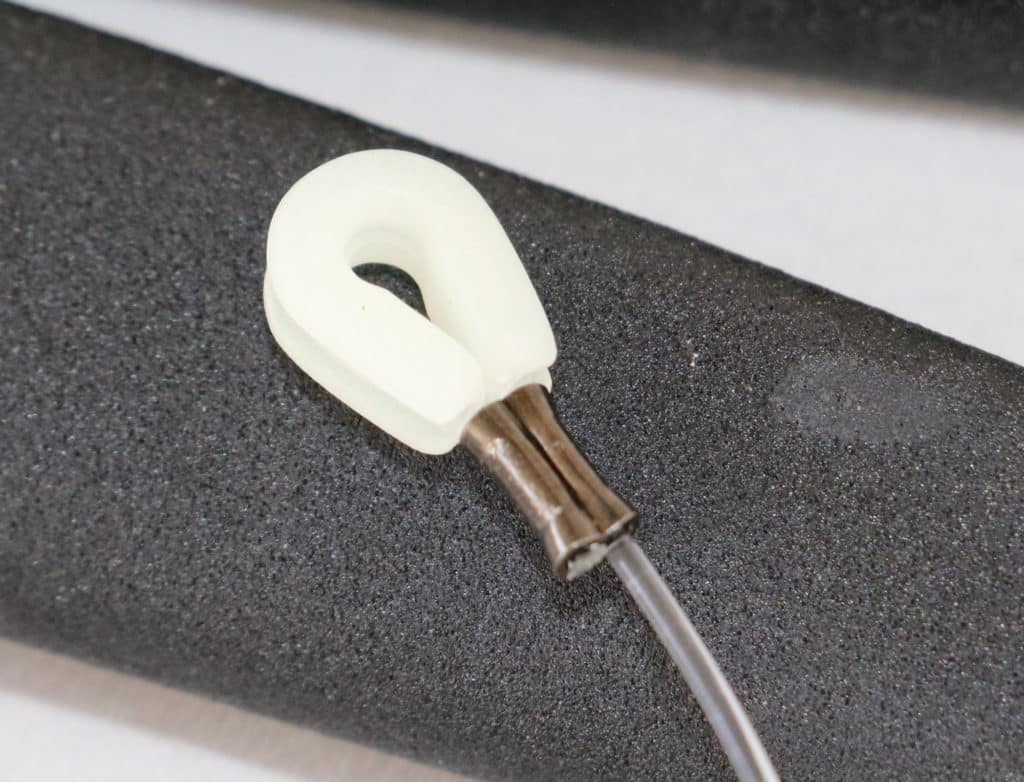

Chafe Protection

Chafe protection such as thimbles or tubing keep the leader loop from wearing thin while trolling or battling a fish. “I like to use chafe protection when fishing marlin,” Rotello says. “This is especially important around the hook since a marlin’s bill and mouth are about the same as 60-grit sandpaper.” As with crimp sleeves, thimbles and chafe tubing need to be matched to the diameter of the leader line.